Future Skills

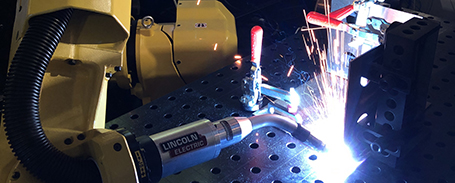

Robotic Welding

Robotic welding is an automated welding process that includes work of special robotic arms and automatic welding equipment. The key advantages of a welding robot are first-class quality and high performance.

Welders require the skills to programme and maintain robots; design, welding equipment use; control over the welding cycle; technical drawings preparation, producing flowcharts, and adjusting the equipment.

Robotic welding is one of the most common robotic applications in the industrial sector, being driven mainly by the automotive sector. Robotic welding is most productive when completing high-volume, repetitive welding tasks.